- Market Sector

- Application Function

- Products

- Geotextiles

- Geocomposites

- Geocomposite Drains

Geocomposite Drains

Terram geocomposite drains are designed to replace 'traditional' solutions and are highly effective in the collection and conveyance of both liquids and gases. - Salt Barrier Geocomposite

Salt Barrier geocomposite

Developed to prevent damage caused by the capillary rise of saline groundwater into 'sweet' soil zones. - Frost Blanket Geocomposite

Frost Blanket

A purpose-designed, protection geo-composite for mitigating the effects of frost heave. - PW2 (Railway Track-bed Drains)

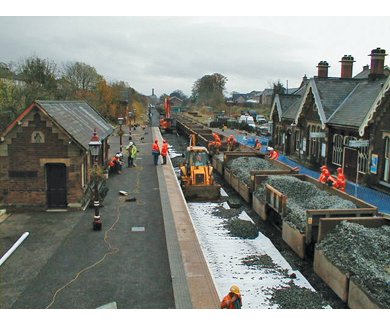

PW2 trackbed robust separator

A robust separator / filter incorporating a stiff net between two textile filter layers.

- Geocomposite Drains

- Geocells

- Erosion Control

Erosion Control Geocell

Terram geocell is a relatively shallow cellular confinement system which is used to combat erosion on slopes up to 1:1. - Retaining Wall

Soil Structure Geocell

Terram Series 500 Geocell provides a cost-effective alternative to conventional earth retention structures. - Tree Root Protection / Load Platform Geocell

Tree Root Protection Geocell

Terram geocell is a cellular confinement system that is used to protect tree roots from damage caused by heavy vehicles.

- Erosion Control

- Geonets

- Landscape Fabrics

- Consumer / DIY

- Downloads

- About Us

- Contact Us

A geosynthetic provides one or more of four functions when used in track-bed construction: Separation to maintain the integrity of adjacent soil types i.e. prevent intermixing. Filtration to prevent leaching of soil particles. Drainage to allow the free passage of water. Reinforcement to provide additional strength.

Preventing sub-grade erosion

Products

Preventing sub-grade erosion with fine soils, coarse soils and granular soils i.e. sand and gravel

Preventing sub-grade erosion with fine soils

Fine soils are mixed soils, containing possibly all the grading sizes including clay silt, sand and gravel. The clay and silt fractions dominate its engineering properties/behaviour. Sub-grade erosion over fine soils can be prevented by the inclusion of a Hydrotex geocomposite at the ballast/subgrade interface.

Preventing sub-grade erosion with coarse soils

Coarse soils are mixed soils containing possibly all the grading sizes including sand, gravel, silt and clay. The sand and gravel fractions comprise over 65% of the soil and dominate its engineering properties/ behaviour.

One of the most common subgrades comprises worn ballast, silt from the degraded ballast, sand, ash, and perhaps some silt and clay contamination. This can fall in the category of coarse soil.

With subgrade erosion conditions, the silts and clays will have been washed out from the coarse soil immediately beneath the geotextile and been pumped through the geotextile to contaminate the lower ballast. Stable conditions will have been established when the washing out of the fines will have created a zone of granular particles immediately beneath the geotextile. Subsidence will have been minimal for a coarse soil dominated by sand and gravel because the fines can be washed out without the soil structure collapsing. A natural soil filter can then form below the granular zone thus preventing remaining fines being washed out.

This mechanism has been confirmed by reports of where silts and clays have contaminated the lower 25 to 50mm of the ballast at which point the contamination has ceased.

The Engineer needs to decide if contamination of the lower ballast is acceptable. If not, a sand blanket augmented by TERRAM PW1

can be used.

If some contamination can be accepted, the use of PW1 directly on top of the coarse soil, without a sand blanket, may be considered appropriate. It is recommended that this solution is only adopted if the percentage of silt and clay fraction in the coarse soil is less

than 15%.

Preventing sub-grade erosion with granular soils

i.e. sand and gravel

If ballast is to be placed directly on a loose, slightly silty, fine to medium sand with occasional gravel, and there is a high water table, then TERRAM PW1 will aid the construction process over what would be difficult ground. In addition, PW1’s pores will prevent leaching of the sand whilst allowing easy passage for the ground water expelled when the line is trafficked.

TERRAM PW1 Standard filter/separator should be used where there is an existing formation with a small percentage of coarse particles,

i.e. <10% by weight <14mm.

TERRAM PW9 Robust filter/separator should be used in an existing formation with a larger percentage of coarse particles

i.e. >10% by weight >14mm.

Soil conditions can vary considerably along a length of track. In some circumstances PW engineers may consider it to be cost effective to lay a geotextile for the entire length as a precaution against localised subgrade variations.

This approach is particularly relevant when using automatic, ballast-cleaning machines where the subgrade may never be seen.