- Market Sector

- Application Function

- Products

- Geotextiles

- Geocomposites

- Geocomposite Drains

Geocomposite Drains

Terram geocomposite drains are designed to replace 'traditional' solutions and are highly effective in the collection and conveyance of both liquids and gases. - Salt Barrier Geocomposite

Salt Barrier geocomposite

Developed to prevent damage caused by the capillary rise of saline groundwater into 'sweet' soil zones. - Frost Blanket Geocomposite

Frost Blanket

A purpose-designed, protection geo-composite for mitigating the effects of frost heave. - PW2 (Railway Track-bed Drains)

PW2 trackbed robust separator

A robust separator / filter incorporating a stiff net between two textile filter layers.

- Geocomposite Drains

- Geocells

- Erosion Control

Erosion Control Geocell

Terram geocell is a relatively shallow cellular confinement system which is used to combat erosion on slopes up to 1:1. - Retaining Wall

Soil Structure Geocell

Terram Series 500 Geocell provides a cost-effective alternative to conventional earth retention structures. - Tree Root Protection / Load Platform Geocell

Tree Root Protection Geocell

Terram geocell is a cellular confinement system that is used to protect tree roots from damage caused by heavy vehicles.

- Erosion Control

- Geonets

- Landscape Fabrics

- Consumer / DIY

- Downloads

- About Us

- Contact Us

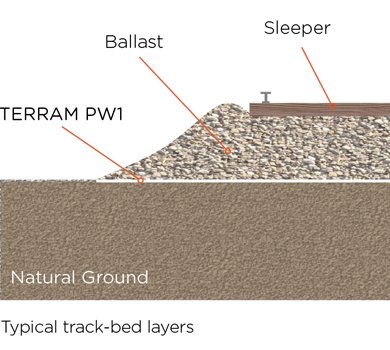

A geosynthetic provides one or more of four functions when used in track-bed construction: Separation to maintain the integrity of adjacent soil types i.e. prevent intermixing. Filtration to prevent leaching of soil particles. Drainage to allow the free passage of water. Reinforcement to provide additional strength.

Extending track-bed life using geosynthetics

Products

With ballast placed directly over a clay or silty subgrade there is the possibility of a slurry being formed at the ballast/subgrade interface; particularly if there are depressions or pockets at formation level.

Regular traffic causes the ballast to oscillate at the interface which disturbs the clay/silt, and the presence of water in the pockets causes the particles to form a slurry. As the ballast dilates, the slurry moves into the void. The slurry is pumped upwards as the ballast contracts. This rapid, cyclical effect causes the mobile clay/silt particles to be forced progressively up into the ballast.

An alternative to using a graded sub-ballast in this situation is described in Railtrack’s Line Code of Practice - Track Substructure Treatments 2 and 3 which describes a blanketing sand of specified grading is laid on the sub-grade to act as a fine soil filter/separator to prevent ‘pumping’.

Using a filter/separator to replace part of a sand blanketOne of the purposes for using a sub-ballast or a sand blanket is to filter any ground-water so that the ballast does not become contaminated with soil particles as a result of sub-grade erosion.

Contamination would cause loss of ballast friction and deformation due to reduced load-bearing capacity in the subgrade. The resulting effect on track alignment would mean a reduction in track speed and, ultimately, track renewal.

A 300mm deep layer of sand was originally introduced in the UK to prevent ballast contamination but it was later found that this could be reduced to 100mm if a geotextile filter/separator was used at the sand/ballast interface – TERRAM PW1. Although this geotextile allows downward movement of water coming via the ballast the relative change in permeability at this interface means this water drains laterally to track-side drains.

Sand does not contain the graded-gravel fraction of a sub-ballast and is thus prone to intermixing with the ballast. PW1 also acts to prevent this. Unlike sand, TERRAM PW1 is compact to transport and is rapidly laid ready for placement of the ballast. It has factory-controlled properties which do not rely on the need, unlike sand, for the correct thickness to be laid consistently across and along the track. In addition, excavation and the attendant disposal of fill is reduced when a geosynthetic is used to reduce the sand-blanket depth.

PW1’s ability to act as a filter over the design life is proven in countless projects around the world over the last twenty five years. Localised excavations along 8 to 10 year-old installations have revealed the PW1 to be in good condition and visual inspection provided confidence that it would continue to do its job. One of the reasons for its longevity is thought to be that the sand provides a cushioned support to the PW1 and this prevents puncture and abrasion by the ballast.