- Market Sector

- Application Function

- Products

- Geotextiles

- Geocomposites

- Geocomposite Drains

Geocomposite Drains

Terram geocomposite drains are designed to replace 'traditional' solutions and are highly effective in the collection and conveyance of both liquids and gases. - Salt Barrier Geocomposite

Salt Barrier geocomposite

Developed to prevent damage caused by the capillary rise of saline groundwater into 'sweet' soil zones. - Frost Blanket Geocomposite

Frost Blanket

A purpose-designed, protection geo-composite for mitigating the effects of frost heave. - PW2 (Railway Track-bed Drains)

PW2 trackbed robust separator

A robust separator / filter incorporating a stiff net between two textile filter layers.

- Geocomposite Drains

- Geocells

- Erosion Control

Erosion Control Geocell

Terram geocell is a relatively shallow cellular confinement system which is used to combat erosion on slopes up to 1:1. - Retaining Wall

Soil Structure Geocell

Terram Series 500 Geocell provides a cost-effective alternative to conventional earth retention structures. - Tree Root Protection / Load Platform Geocell

Tree Root Protection Geocell

Terram geocell is a cellular confinement system that is used to protect tree roots from damage caused by heavy vehicles.

- Erosion Control

- Geonets

- Landscape Fabrics

- Consumer / DIY

- Downloads

- About Us

- Contact Us

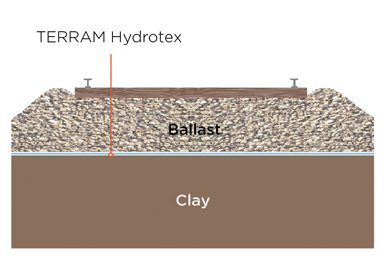

A geosynthetic provides one or more of four functions when used in track-bed construction: Separation to maintain the integrity of adjacent soil types i.e. prevent intermixing. Filtration to prevent leaching of soil particles. Drainage to allow the free passage of water. Reinforcement to provide additional strength.

Preventing Clay Pumping

Products

Placement of a sand blanket is time consuming and time is of the essence when working against the possessions’ clock.

Replacing a sand blanket entirely

Manufacturers have continued to develop and evaluate likely candidates for a sand-blanket replacement knowing that the ideal product would have to be:

• Quicker to install

• Lower in (installed) cost

• More readily available

• More environmentally friendly

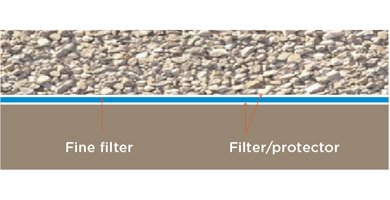

Fiberweb Geosynthetics recognised that its own development needed to be focused on the filter function as PW1 alone is not capable of preventing the passage of the smallest clay/silt particles. Fiberweb plc has a great deal of expertise in non-woven filters and this became available when Terram Ltd was acquired by

Fiberweb plc.

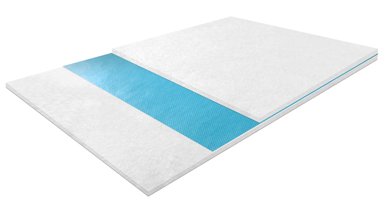

Fiberweb developed a filter that was more than capable of preventing the passage of the smallest clay and silt particles. The only complication was that these filters are not particularly robust and would not survive the rigours of track-bed use on their own. The solution was to sandwich the filter at the centre of two robust layers of geotextile to protect it from potential damage. The result was the Hydrotex range of geocomposites.